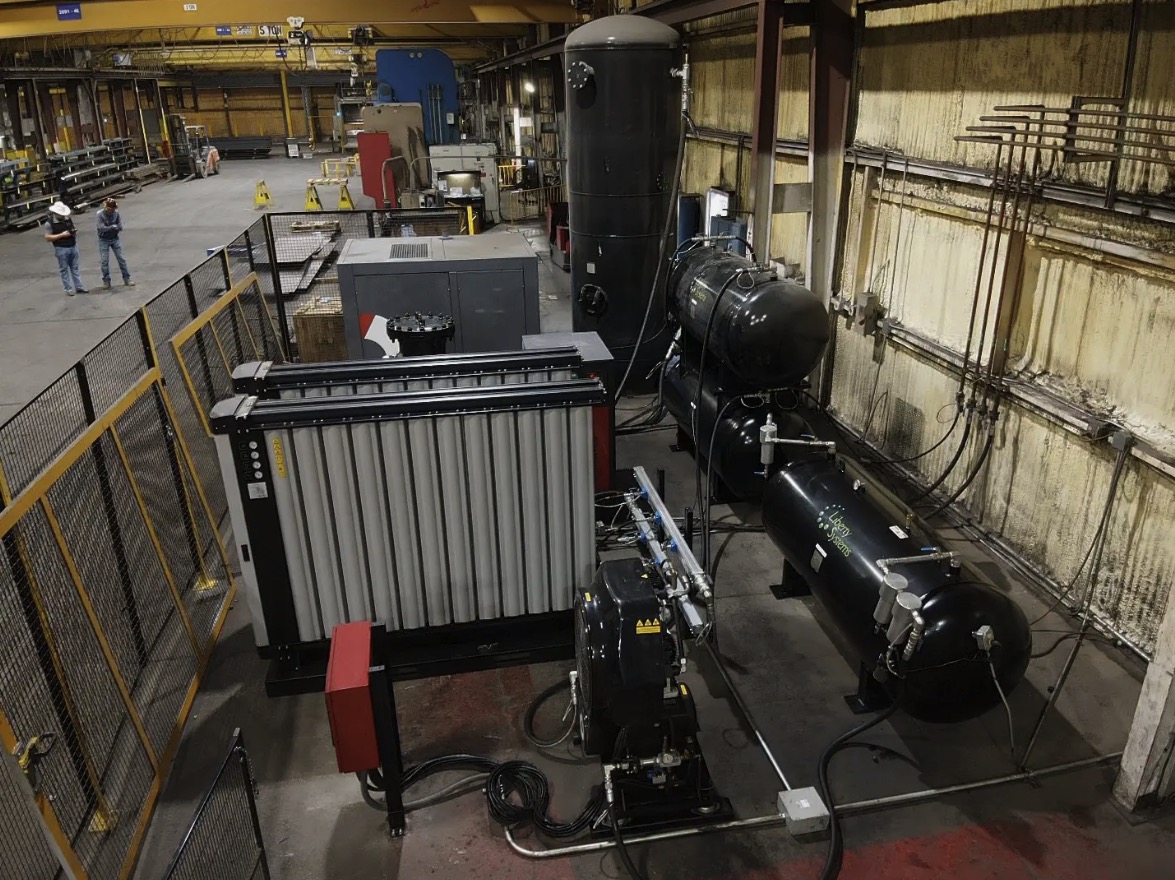

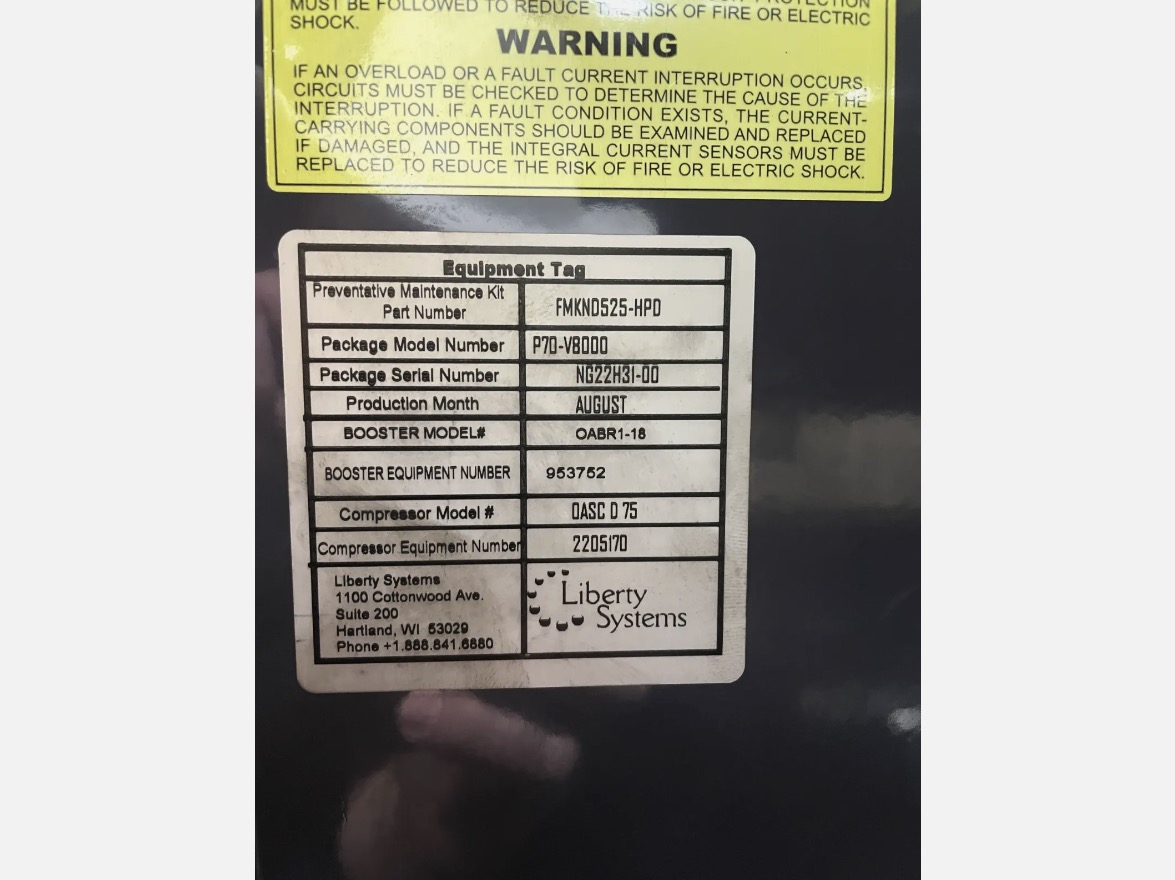

2022 Liberty Systems P70-V8000 Nitrogen Generation System

2022 Liberty Systems P70-V8000 Nitrogen Generation System

Location:Fort Worth, TX

Description

COMPLETE SYSTEM

- Model: P70-V8000

- Flow Rate: 8,000 scfh

- Purity: 99.50%

- Delivery Pressure: 400 PSIG

- Air Compressor 75kW (100 HP)

- Voltage: 460/3ph

- Booster Compressor: 18 kW (25HP)

EQUIPPED WITH: Ozen Air Compressor, Refrigerated Air Dryer, Condensated Oil/Water Separator, Compressed Air Tank, Oil Mist Eliminator, Compressed Air Filtration Assembly, Nitrogen Generator, Booster Compressor, High Pressure Vessel

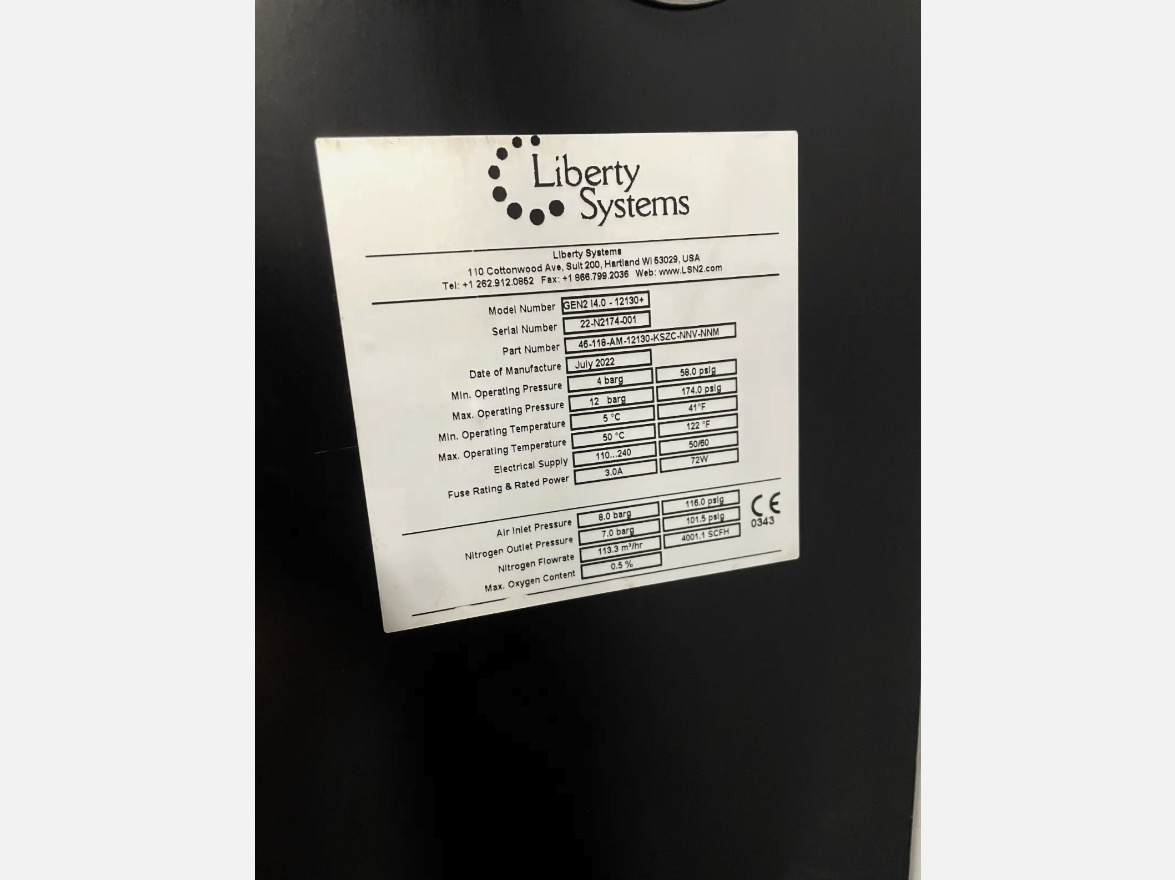

NITROGEN GAS GENERATOR PACKAGE

Nitrogen Generator

Touch screen Display

Multiple screens allowing set-up, alarm list and oxygen calibration

Output nitrogen purity analyzer

Dry alarm contacts, 4-20 mA output

svstcm standby/ hibernation

Nitrogen dew point -70° F

Locking handle inlet and outlet isolation valves

Nitrogen Buffer Tank

ASME /CRN

Pressure relief valve (certified)

2" dial pressure gauge

Locking handle inlet and outlet isolation valves

Manual blow down valve

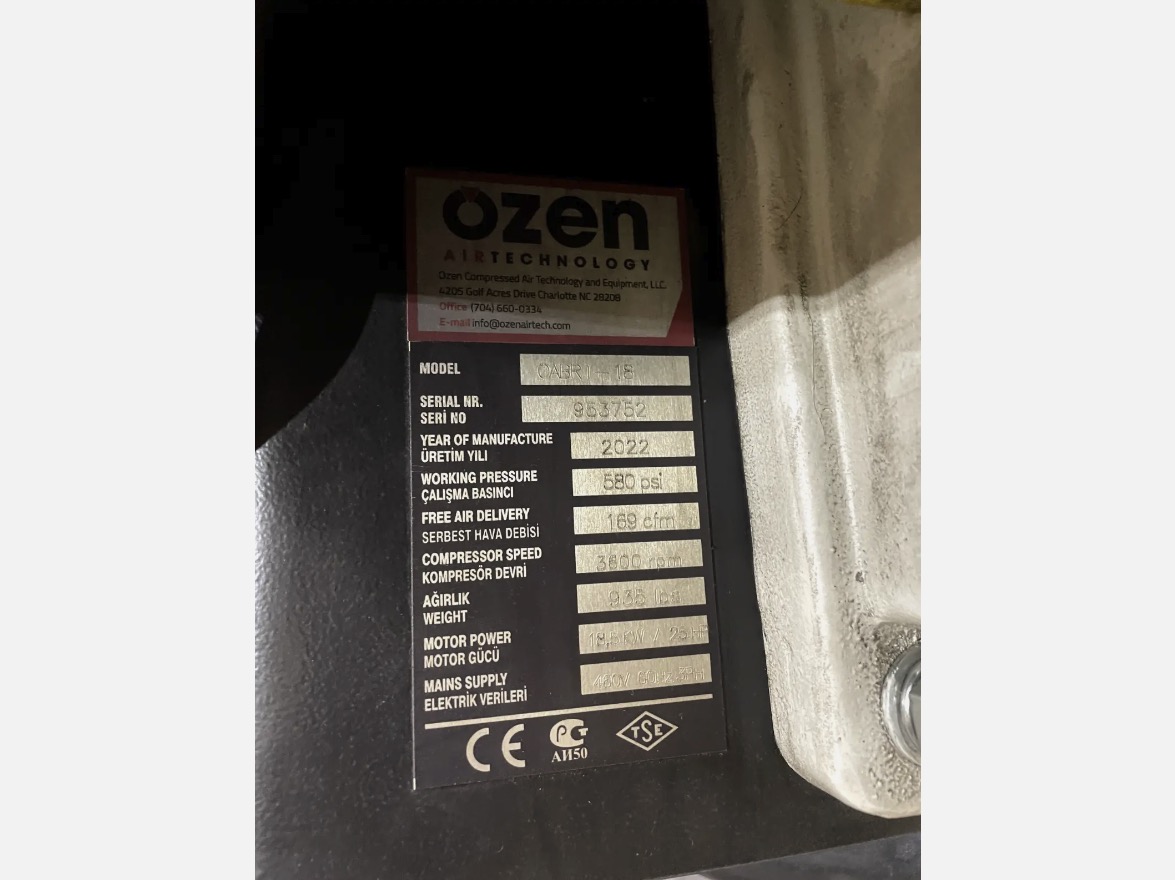

HIGH PRESSURE GAS PACKAGE

Booster Compressor 460/3/60

18 kW (25 HP) Variable frequency drive oil injected rotary screw booster compressor

TEFC Motor

Prewired controls

Compressor carries NEMA 1 classification

Integrated compressor electrical cabinet carries a NEMA12 classification

Locking handle Inlet and outlet isolation valves

High Pressure Vessel

ASME / CRN

Pressure relief valve (certified)

2" dial pressure sauge

Inlet and outlet isolation valves

Manval blow down valve

Locking handle inlet and outlet isolation va:lves

Four Stage High Pressure Filtration Assembly

1.0-micron coalescing

0.01 micron particulate

0.003 micron vapor removal

Sub-micron particulate filter cleaned for laser service

Installed at laser inlet

Locking handle inlet and outlet Isolation valves

COMPRESSED AIR PACKAGE

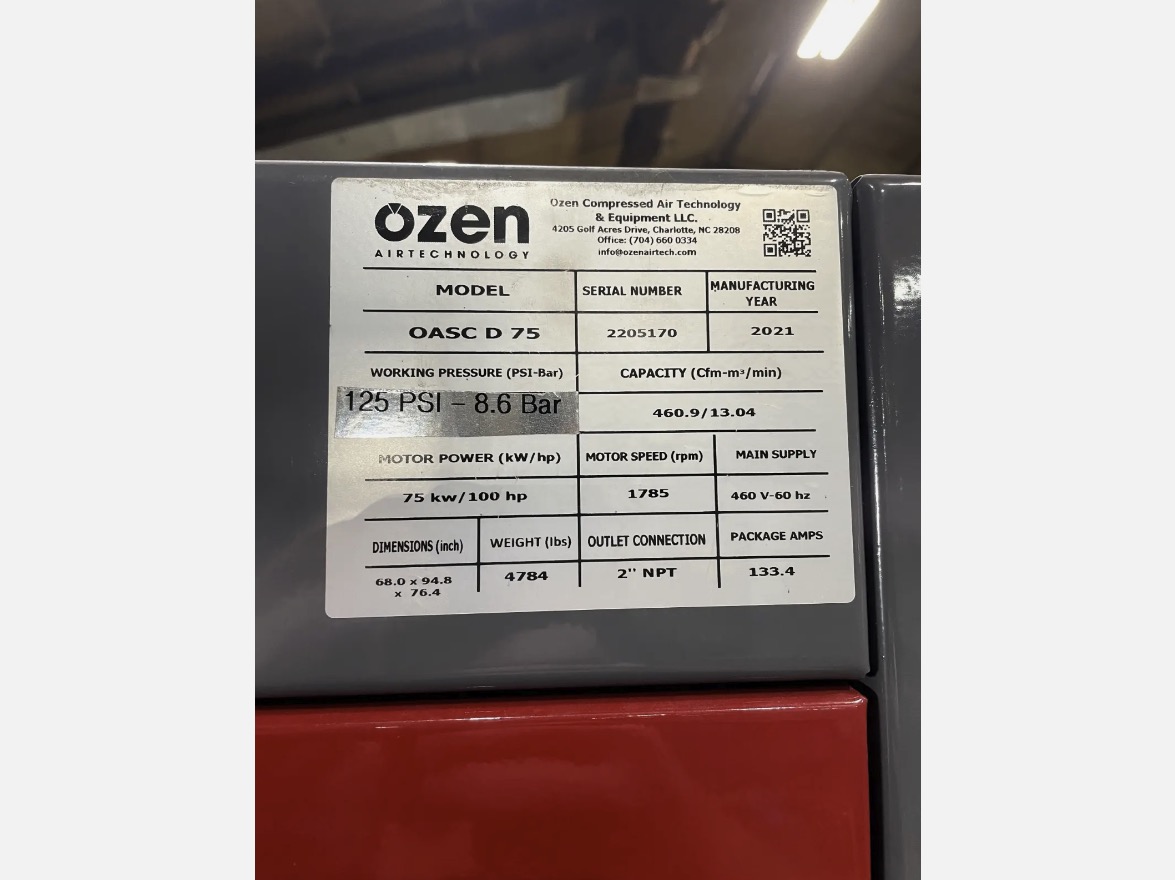

Air Compressor 460/1/60

75 kW (100HP) Variable frequency drive oil injected rotary screw air compressor

TEFC motor

Efficiency = 90.2%

Compressor carries NEMA 1 classification

Integrated compressor electrical cabinet carries NEMA 12 classification

Locking handle inlet and outlet isolation valves

Refrigerated Air Dryer

Direct Thermal exchange with thermal storage

Stainless steel centrifugal separator

Oversized copper tubind reducing pressure loss

Cycling type

Locking handle inlet and outlet isolation valves

Condensate Oil / Water Separator

Liberty Systems provides a solution for the oily condensate that is a by-product of air compression. As your air compressor draws in ambient air for compression, the moisture present in that air is also compressed. We take several steps to try and eliminate it. The compressed air tank, refrigerated air dryer and compressed air filters all play a role in this process. The condensate is filtered in a condensate oil/water separator. This allows you to stay EPA compliant and dispose of the filtered water down a drain or on the grass.

Compressed Air Tank

Our compressed air tanks are generally sized at a 3:1 or 4:1 per scfm ratio for load/ unload air compressors and 2:1 or 3:1 per sdm ratio for variable frequency drive air compressors. This is an engineering choice by Liberty Systems to reduce the load/ unload cycle frequency of the air compressor.

ASME / CRN

Pressure relief valve (certified)

2" dial pressure gauge

Locking handle inlet and outlet isolation valves

Manual blow down valve

Oil Mist Eliminator

ASME / CRN

Pressure relief valve (certified)

2" dial pressure gauge

Locking handle inlet and outlet isolation valves

Manual blow down valve

Compressed Air Filtration Assembly

Water separator

Includes Zero Loss Magnetic Drain

1.0-micron coalescing

0.01 micron particulate

0.003 micron vapor removal

Locking handle inlet and outlet isolation valves

Specifications

| Manufacturer | Liberty Systems |

| Model | P70-V8000 Nitrogen Generation System |

| Year | 2022 |

| Condition | Used |